I've installed the sprite pro on my ender 3 max. To get it going I compiled my own firmware and found that TH3D's firmware was simple and worked well.

Although it wasn't long and I added an rpi and installed Klipper.

For the bltouch, I didn't really spend time on it. The connector to the included board on the extruder didn't work - - I ran my own wire directly to the main board. Likely user error, but it's working so I stopped trying to fix it.

Hope this helps.

I run linux on my gaming rig. I've had the best luck with performance of graphics cards with manjaro and pop. I am not a huge fan of gnome and prefer kde (FWIW, gnome works fine, I just prefer the feel of kde).

With the above in mind, I really like the newness of the packages on rolling distros like Manjaro/arch. Yes, it can break things but Manjaro tends to be a bit behind Arch on releases -- maybe this helps? The AUR is awesome. I also like several of the gui tools Manjaro has implemented to make graphics driver installs simpler.

Pop worked really well and was simplier for gaming -- especially on devices with hybrid graphics.

That being said, I haven't used Mint since the forums were hacked. I haven't used Ubuntu since they started devaluing their users (integrated Amazon?, forcing snap?). Fedora is nice but I found pop/manjaro better for gaming due to graphics support.

My advice to you -- what you are asking is one of the main benefits of linux -- personal choice.

So... get out your USB stick and try them. Use the forums to help you with the nuances and make each work for your needs. Then see what you prefer. Then donate to that project and its base project.

It's awesome to have choice.

So, I bought myself a rpi4 and installed Klipper. Very cool firmware quite enjoying it. Still tuning but i've got my speed up 3x from my Marlin based firmware. I think I'll continue looking at the options here recommended and build one -- mostly because I want to -- not because I am solving a problem. Thanks for putting me onto Klipper.

Thank you everybody for leading me on the right path.

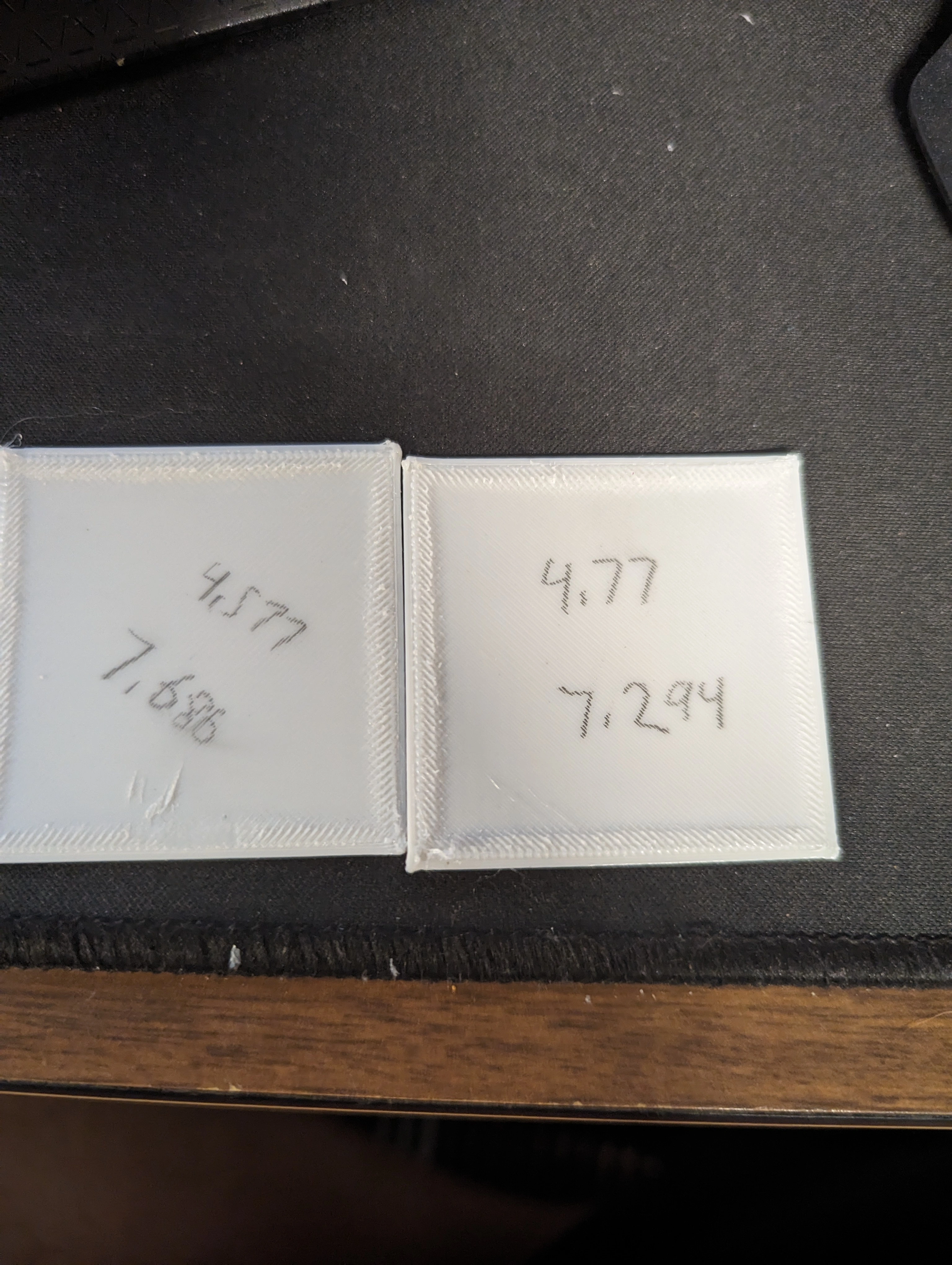

As I had already installed Klipper, I decided to try the pressure advance calibration as suggested and it did take some tuning, but has improved quality immensely.

In the end, here are the settings I changed: Klipper printer.cfg pressure_advance: 0.120

PrusaSlicer:PrinterSettings:Extruder 1:Retraction Length: 0

I still think I can tweak my z-offset and temperature and maybe further refine pressure_advance, but the results are quite a bit better than before.

I used the Klipper guide for pressure advance: https://www.klipper3d.org/Pressure_Advance.html

Original print on the left, print with the above changes on the right.

Having said that, I think I might have been able to improve the results using a marlin firmware and working with my retraction setup -- I use a non-default direct-drive extruder so the default settings of about 6mm are certainly incorrect.

Also, into the future, i'll check out the wear/maintenance on the nozzle -- it is a good point and I havent changed it in quite a few prints.

Thank you everybody!

I've never really thought much about something specific for petg.

I use a magnetic pei bed, both textured and non textured with a glue stick layer.

I don't often need to clean but I'll use soap and water in the sink for the majority and then a isopropyl squirt and rub with a rag. Then I reapply glue stick.

This lasts a lot of prints for me for pla, petg and abs.

Really, I'd think you would need to avoid chemicals that would react with your bed and make sure there is no residue left by your cleaner. For my pei bed I bet I could even use acetone. Beyond that... Happy washing.

There are lots of internet gudes on this. Here is one random one I just found. https://www.wevolver.com/article/how-to-clean-3d-printer-beds-glass-pei-adhesive

No, overlap settings are default. Taller objects or objects with infill come out okay - workable but still show small signs of the issue. I've found the 5+ layer object with no infill showes the issue the most so I've been using that to tune.

You are absolutely correct that first layer tends not now show issues like zOffset to close to bed or over extrusion. The prints I've been using are 5+ solid layers to have any offset alignment or extrusion alignment issues increase with each added layer.

Yes. For this petg I've tried nozzle temps ranging from 210-240.

So... I still have some tuning.

I learned that you need to adjust retraction and z offset again after implementing pressure advance.... But I'm close now.

Oh boy... Yes scripting comes easy to me. It's why my default is openscad for making 3d models. :). I'm printing the pressure advance cube model now.

I agree, not just the perimeter but also when it's going back and forth to fill in the centre area. I'm not sure how to address it -- maybe the pressure advance settings LazaroFilm suggested. I've also tried printing at a series of different temperatures..

I'll check that out. I installed klipper yesterday for S&G -- actually quite liking the flexibility it gives me. I see the guide.

in those two cases, they are PETG and bed temp was 80. The curved edges were caused by me removing the print from the hot bed.. not lifting off during the print.

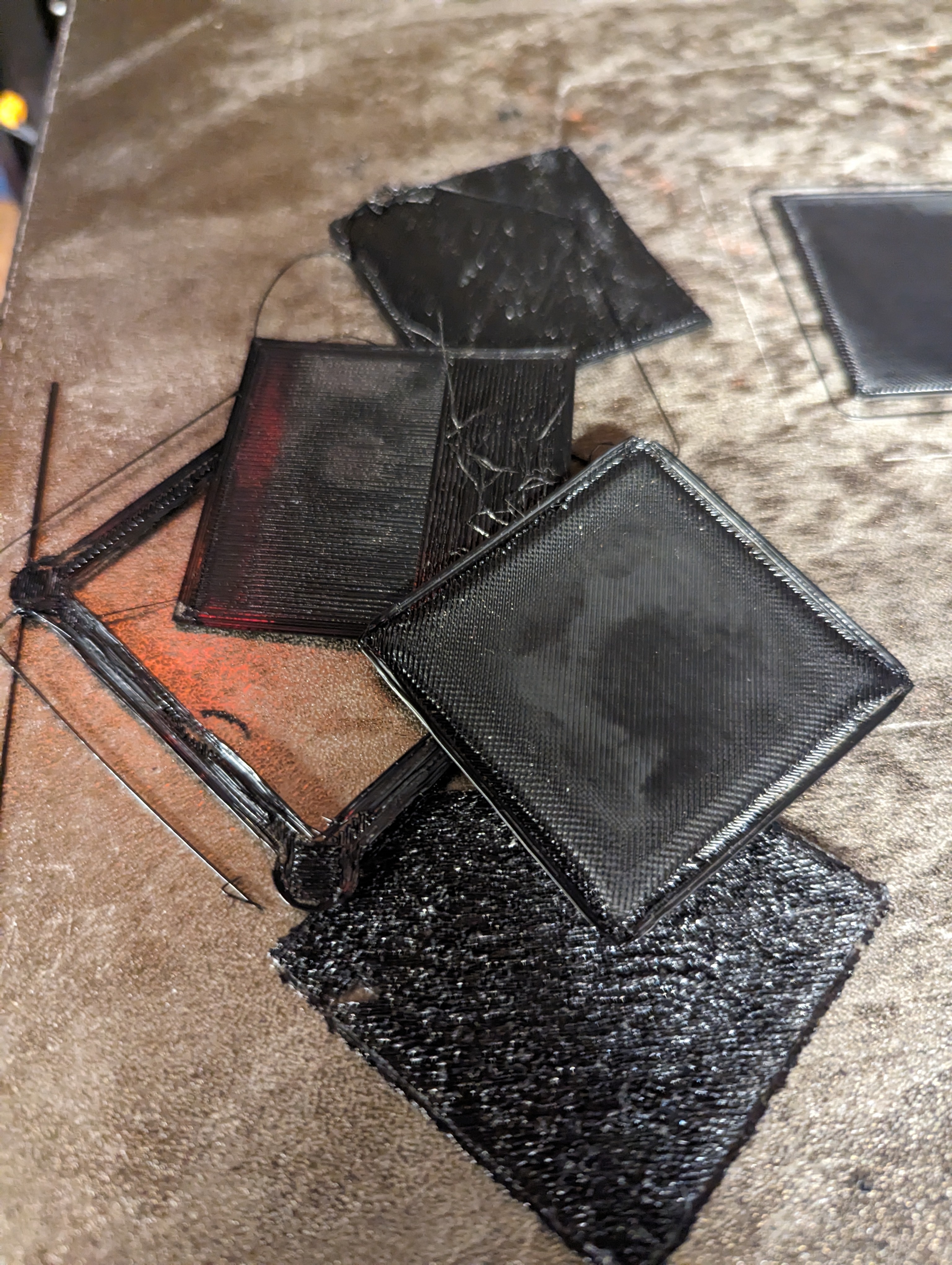

Messy edges on my prints

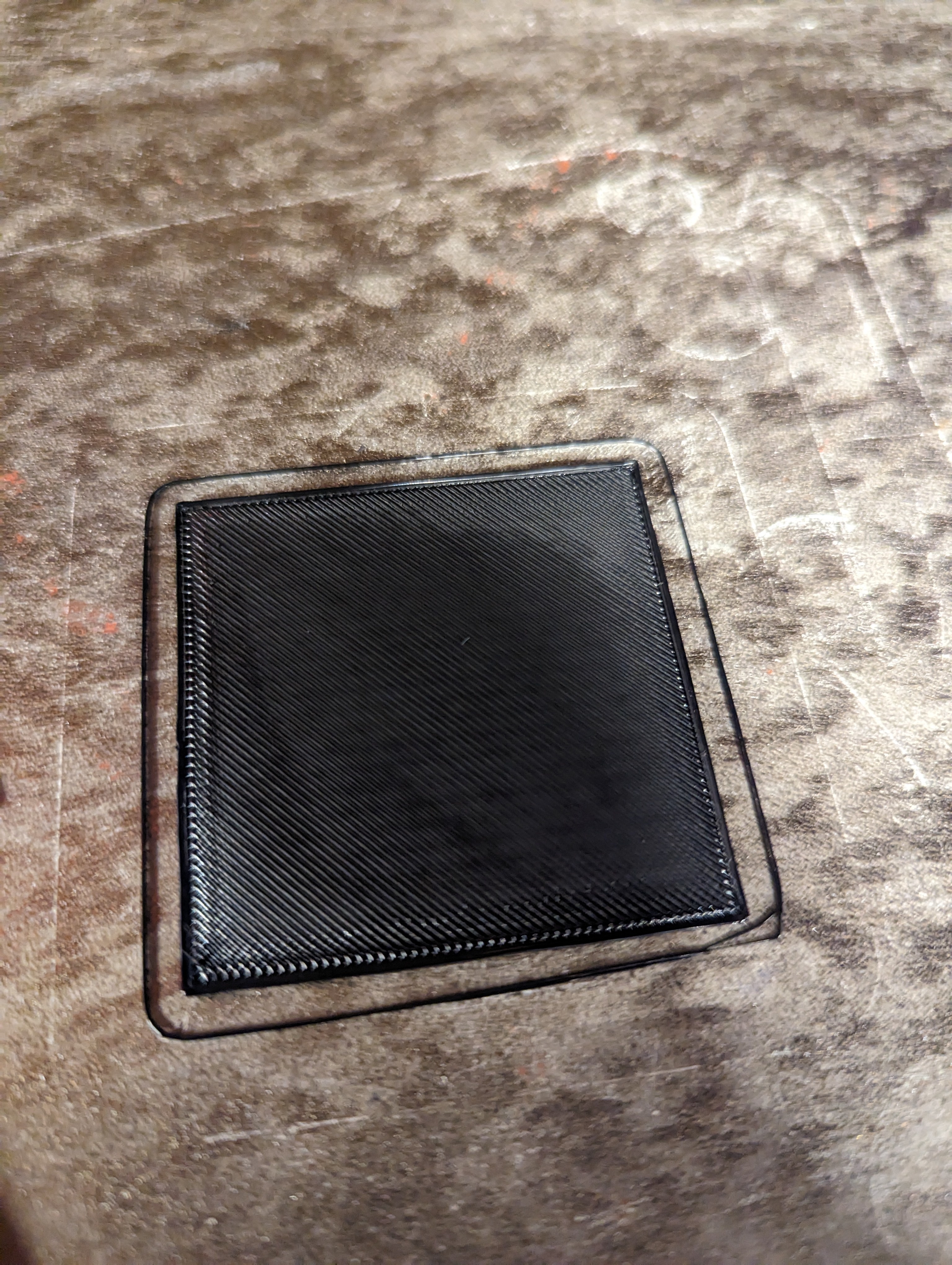

I'm trying to diagnose what tuning I need to get a smooth top layer on a solid print.

The picture you see is a 50mmx50mmx1mm square (cube([50,50,1]); in openscad) printed with a .4 nozzle. (5 layers)

For tuning on the problem, I have looked into:

- z_offset -- tried all kinds of values and if I reduce it anymore, it doesn't squish into the bed and the center part is exactly 1mm -- so unlikely to be that.

- bed level -- bltouch is working well

- extrusion (esteps or rotational_distance) - played with this a great deal and any less and i start to have under-extrusion in the center area.

- different filament -- same with PLA, PETG and ABS

- Different slicer -- same with PrusaSlicer or Cura

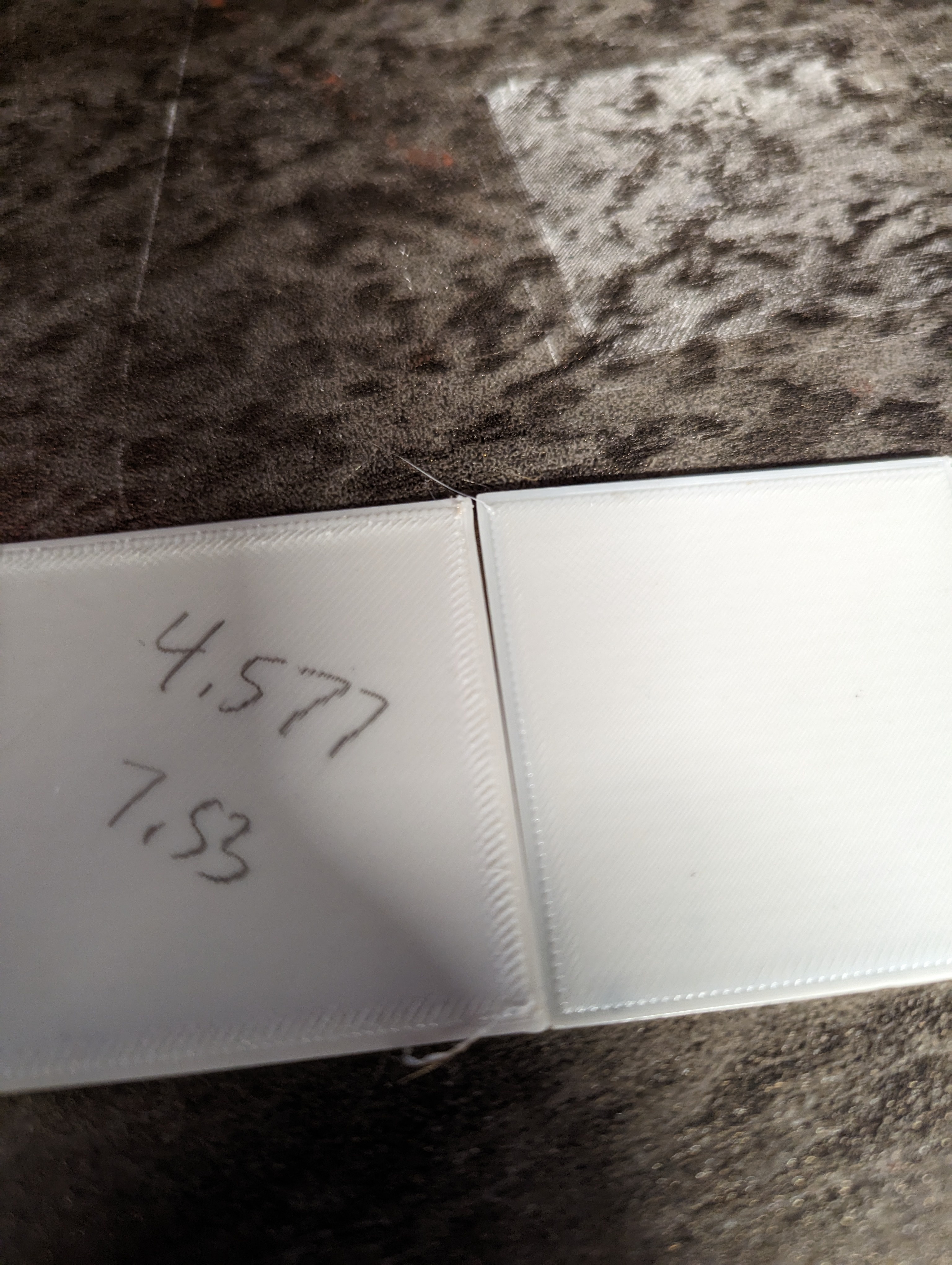

- Different speeds -- one on the left was printed at 20mm/s -- the right was printed at 150mm/s

I also cant find any guides out there that show this issue. Anybody with some suggestions or threads I can pull?

Yeah. If you are good for pla, it's not likely the cause.

Thanks! I hadn't considered the slicers. I don't have a driving need multi-matrtial -- mostly considering that if I'm going to invest in building a printer, I'd want it to be capable in all ways.

Thanks. My main speed issue, I think, is the size of the bed. My base unit was an ender 3 max with a 300x300 bed. On a fast print that bed swings with enough energy to actual move the printer.

I say likely is that I haven't attempted to solve the issue yet -- I don't need the speed, I simply enjoy tinkering and this is one are I havent.

Having said that, from the original post, while I want to build one from scratch, I'll probably continue tinkering on my custom printer as well.

I've played with up to a 1.0mm nozzle -- haven't had results yet.

I had similar messy results at one point -- it tuned out to be a bad zOffset. Having said that, my part also as a messy top layer -- not sure if yours has that or not with the little nub there.

Im also all Linux and like many of the other commenters, I mainly use openscad as my primary and freecad. There is a lot of free training video and walkthroughs for both.

Awesome. Thank you for the reply. Sounds like it is time to start printing and collecting parts.

voron 2.4 - anybody with actual experience

Get started with VORON 3D printer, the best little CoreXY 'space shuttle' you can build in your garden shed, or your kitchen.

Hello,

I was interested in building a high end printer, mostly for the fun of it and learning what goes into it. I've been looking at the Voron and on the page looks really nice; however, I've been unable to find a lot of actual print quality, speed, and capability comparisons.

Does anybody here have experience or recommendations of other high end, self build, printer designs?

I'd be using my customized printer based on the ender 3 max platform.

Really, looking to improve in a few areas:

- proper enclosure and venting so I don't continue to poison myself when printing abs.

- elimination of ringing caused by that heavy bed swinging around at high speed

- ability to ramp up the print speed past 50mm/s

I'd also love the ability to play with multi-matrtial printing, but not high on the list.

Thanks all